Soybean Protein Processing Plant

Soy protein concentrate is produced from soybeans through a series of processes, including crushing, dehulling, extraction, separation, washing, and drying, to remove oil, low-molecular-weight soluble non-protein components (primarily soluble sugars, ash, alcohol-soluble proteins, and various odoriferous substances). The resulting product contains at least 65% protein (N x 6.25) on a dry basis.

Henan Huatai Intelligent Equipment Group can provide you with complete set of soybean protein processing plant solutions, and offer complete turkey projects.

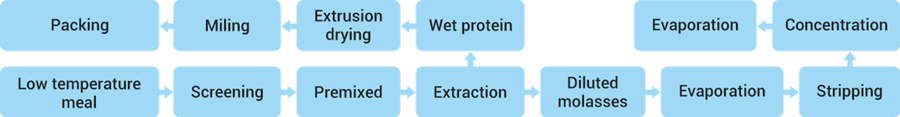

Alcohol method soy concentration protein process diagram

Alcohol Method Soybean Concentration Protein Process

The production process utilizes a fully continuous alcohol-washing process, no wastewater discharge during production process.

Adopt American alcohol-washed soy protein concentrate technology, produce up to 100,000 tons/year of soy protein concentrate annually.

A single production line can produce both feed-grade and food-grade soy protein concentrate.

A triple-effect evaporation system improves steam utilization.

Distillation technology increases syrup concentration while eliminating odors in the ethanol.

Extrusion technology increases protein content while conserving steam.

The production line uses fully computerized automatic control to ensure stable process parameters.

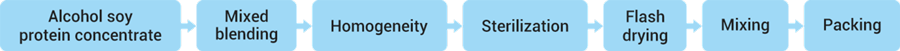

Functional soy concentration protein process diagram

Functional Soy Concentration Protein Process

Adopt American ADM Company advanced functional soybean protein concentrate technology.

Use a new method of adding ammonium hydroxide instead of sodium hydroxide, the finished product is salt-free.

Adopt a combination of enzyme modification, shear modification, and heat treatment modification processes.

Adopt high-temperature and high-pressure physical modification technology, with pressure reaching approximately 40 MPa.

After modification, some functional indexes exceeded the standard of soybean protein isolate.

The production line uses fully computerized automated control to ensure stable process parameters.

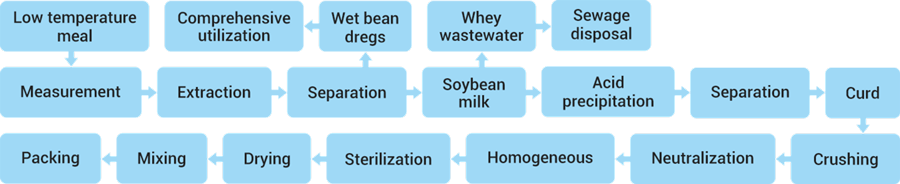

Soybean protein extraction diagram

Huatai Group Soybean Protein Extraction Process Features

Adopt mature domestic and foreign full continuous acid-base production process.

Integrates American and Japanese soy protein isolate process technologies.

Stable product quality, with a yield of up to 45%.

The output of a single spray drying tower is 20,000 tons/year.

Separation and extraction of functional soy protein isolate components further enhances product functionality.

Adopt a continuous neutralization system to ensure product color does not deepen.

Adopt enzymatic hydrolysis and spray coating technologies to expand product variety.

Use the comprehensive utilization of soybean dregs and whey water to address environmental concerns and improve economic efficiency.

The production line use fully computerized automated control to ensure stable process parameters.

Soybean protein extraction process

Henan Huatai Group soyban protein concentration project independently develops and designs efficient, economical, and reliable processes and equipment.

This process overcomes traditional limitations and utilizes integrated soy protein concentration equipment manufactured by Huatai Group, include softening kettles, extractors, degassing and deodorizing towers, stripping towers, dryers, decolorization, desolventization, and deodorization towers, crystallizers, and oil refining kettles. Feel free to consult us for more information about soy protein extraction!